In order for Switzerland to achieve its goal of net zero greenhouse gas emissions by 2050, there is a great need for carbon capture and storage (CCS) technologies and negative emission technologies (NET) for emissions that are difficult to avoid. These technologies are only partially available and will therefore be tested and researched in the near future. The OPSIS LD500 as a very flexible system is ideal for pilot projects or experimental plants.

The process control of a CO2 capture plant needs good and reliable detection of gas phase NH3 and CO2.

Measuring NH3 is a challenge due to the corrosive environment and high concentrations of NH3. Several places in the process needs to be monitored and to transport the sample is difficult. A large dynamic range is needed

as the NH3 concentration can vary between 15% volume and a few mg/m3.

The process control of a CO2 capture plant needs good and reliable detection of gas phase NH3 and CO2.

Measuring NH3 is a challenge due to the corrosive environment and high concentrations of NH3. Several places in the process needs to be monitored and to transport the sample is difficult. A large dynamic range is needed

as the NH3 concentration can vary between 15% volume and a few mg/m3.

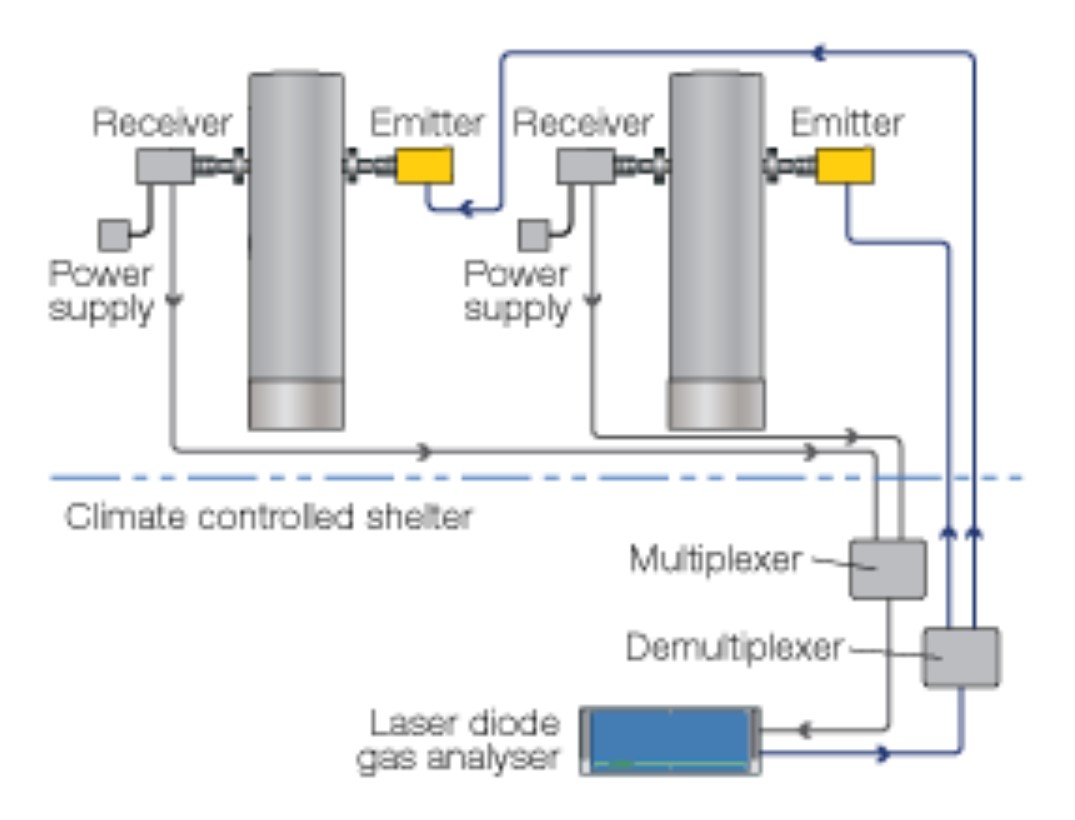

The OPSIS DOAS system is different and provides CO2 capture plants with an accurate analyser that will operate with a minimum of maintenance. The OPSIS DOAS system is based on a non-contact method using an optical measurement path that can operate across the duct. The optical light is transported in an optical fibre to the analyser and one analyser can operate several paths.

Besides the measurements of NH3 and CO2, several other gases can be measured with the same analyser.

Features

- No sampling required, non-contact measurement system

- Operates with a minimum of maintenance

- Best performance according to QAL 1 certification

- Longest calibration interval according to QAL 1 certification

- Low energy consumption

- Gas calibration only once per year

- Internationally approved

- Thousands of systems installed worldwide

- Serviced by highly skilled service network

For further information you can contact us by contact form or Tel: 044 7463220