Lactic Acid Bacteria Fermentation Kinetics Monitoring and Reactor Control

The main function of Lactic Acid Bacteria (L.A.B.) is to produce Lactic Acid, which is the acidification process of foodstuffs. The main application of L.A.B. is as starter cultures in the food industry with an enormous variety of fermented products – dairy, meat, fish, fruit, vegetables and cereal products.

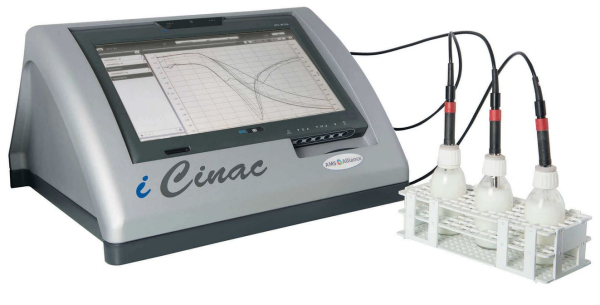

The AMS Alliance iCinac Series is heavily used by ferment and starter culture manufacturers, both for product quality control and development of new cultures for the dairy industry. Monitoring the behavior of these starters allows you to optimize these difficult processes, ensuring consistent L.A.B. activity and consistent quality of the end product.

The iCinac Series is a unique solution for kinetic analysis and monitoring for fermentation L.A.B. reactors, and as a fermentation multi-reactor control unit. It is widely used for monitoring of ferments in starter, functional, bio-protective and probiotic cultures. When iCinac is equipped with its external control module (optional), it can control heating baths, peristatic pumps, circulators, and becomes a complete L.A.B. fermentation multi-position bioreactor platform.

Features

- Unique solution designed for acidification activity of L.A.B.: simultaneous monitoring of pH, temperature, and Oxidation Reduction Potential (ORP).

- Uses ISM® protocol digital electrodes (pH/Temp, pH/ORP/Temp)

- Scalable – up to 32 channels with the wired version, and 16 channels with wireless

- Meets ISO 26323|IDF 213, the industry standard for determining dairy cultures’ acidification activity

- Each electrode or channel is independently monitored while providing full control and insight into each experiment

- Easy-to-use software – results in real-time automatic configuration and detection of connected modules

Benefits

- Ensures inter-batch kinetics consistency in compliance with ISO standards

- Reduces product development timelines because of the reactor-scale, efficient design and your choice of ferment

- Allows you to adapt the configuration to your needs (current and future)

- Wired or wireless version (or combined); select the number of channels, the number of electrodes, and subsequently add or remove electrodes from the systems

- Improves quality control, R&D, product development and process optimization