Universal Scanning Mobility Particle Sizer for various applications from 4 - 1200 nm

The Palas® Universal Scanning Mobility Particle Sizer (U-SMPS) is available in two versions. With a long classifying column (models 2050 / 2100 / 2200) particle size distributions from 8 nm to 1,200 nm can be reliably determined. The Palas® U-SMPS system contains a size classifier (defined in ISO 15900 as Differential Electrical Mobility Classifier (DEMC), also known as Differential Mobility Analyzer (DMA)), in which the aerosol particles are selected according to their electrical mobility and guided to the output.

These particles are then counted by a condensation particle counter (e.g. Palas® UF-CPC). The three available UF-CPC models allow optimized single particle counting in different concentration ranges. Prof. Wiedensohler from Ift (Leipzig) developed the algorithm, which was used by Palas® for the data inversion of the measured data to a particle size distribution for the U-SMPS.

The U-SMPS is operated via a graphical user interface with touch screen. A scan of a particle size distribution can be performed in only 30 seconds or in up to 64 size channels per decade. The voltage in the DEMC is continuously changed, resulting in higher count statistics per size channel. A linear and logarithmic display of the measured values is possible on the device itself via the integrated data logger. The enclosed evaluation software enables a wide range of data evaluations (extensive statistics and average calculations) and offers export options.

The U-SMPS is usually operated as a stand-alone device, but can also be connected to a computer or network via various interfaces (USB, LAN, WLAN, RS-232/485). The Palas® U-SMPS universally supports DMAs, CPCs and aerosol spectrometers of other manufacturers.

Especially for calibration projects, accurate sizing and reliable performance of the U-SMPS are extremely important. All components must pass a stringent quality assurance test and are assembled in-house.

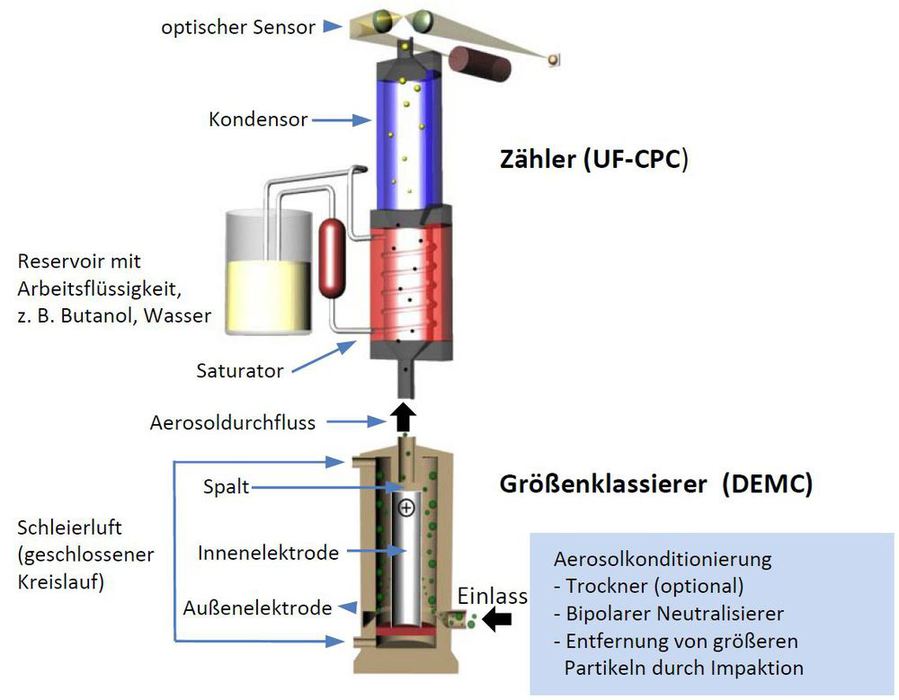

The figure shows the functional principle of the U-SMPS:

Before the aerosol enters the size classifier (DEMC column), it is conditioned. An optional dryer (e.g. silica gel, Nafion) removes moisture from the particles. A bipolar neutralizer (e.g. Kr-85) is used to ensure a defined charge distribution of the aerosol. To separate particles larger than the size range of the classifier, an impactor is required at the inlet of the DEMC.

Functional principle of the Universal Scanning Mobility Particle Sizer (U-SMPS)

The aerosol then passes through the inlet into the DEMC column. The aerosol stream along the outer electrode is then carefully combined with a stream of veil air. It is important to avoid any turbulence to ensure a laminar flow. The surfaces of the electrodes must be of excellent quality in terms of smoothness and tolerances.

The veil air is a dry, particle-free carrier gas (typically air) that circulates continuously in a closed circuit and at a higher volume than the aerosol. The volume flow ratio between particle-free air and air containing particles defines the transfer function and thus the resolving power of the DEMC.

By applying a voltage, a radially symmetrical electric field is created between the inner and outer electrode. The inner electrode is positively charged and has a small gap at the end. By balancing the electric force on each particle with aerodynamic air resistance in the electric field, negatively charged particles are deflected towards the positive electrode. Depending on electrical mobility, some particles pass through the gap and leave the DEMC.

During operation, the voltage and thus the electric field are continuously changed. Thus particles with different mobility leave the DEMC and are counted one after the other by a nanoparticle counter such as a condensation particle counter (e.g. Palas® UF-CPC).

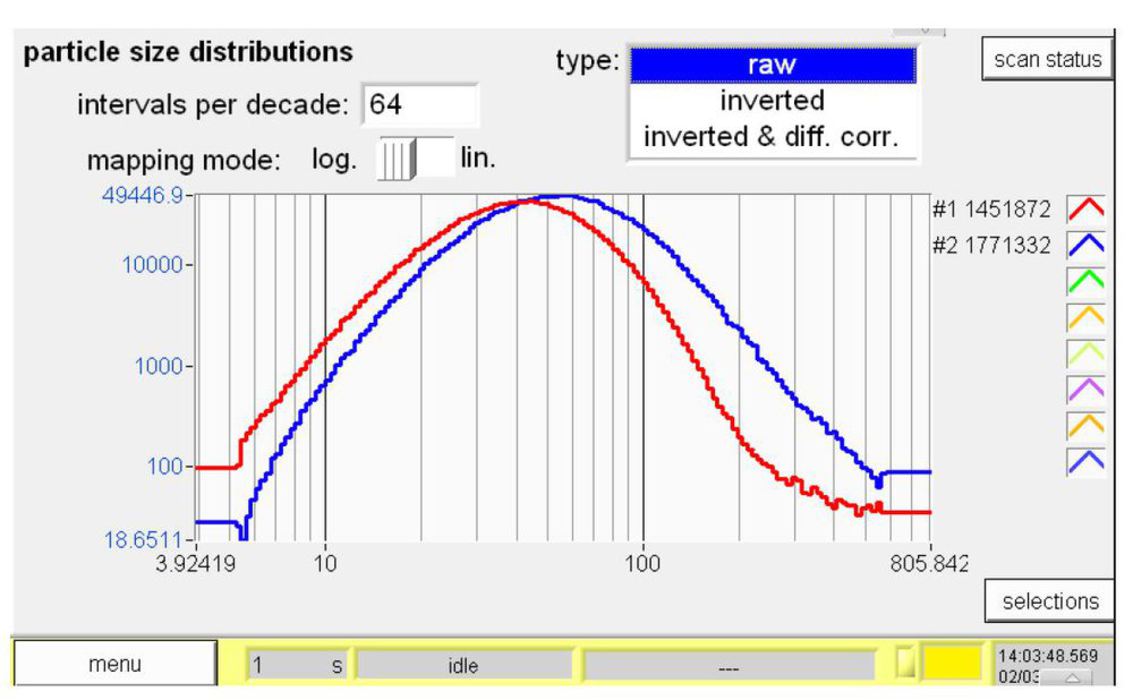

In order to combine the data (voltage, number of particles, etc.) and thus obtain a particle size distribution as shown in the following figure, the proven software offers special advantages.

Particle size distributions of an aerosol of the Palas® DNP 3000 particle generator

User Interface and Software

Based on constant customer feedback, the user interface and software are designed for intuitive operation, real-time control and display of measurement data and parameters.

The software also provides data management with integrated data logger, advanced export capabilities and network support. The measured data can be displayed and evaluated with many available options.

Available Systems

The following document shows the different combinations of the DEMC with the meters available at Palas®. Most DMAs, CPCs and aerosol spectrometers from other manufacturers can be used as components of the U-SMPS system.

Overview of the scanning particle mobility systems U-SMPS 1050_1100_1200 and 2050_2100_2200

Advantages:

- particle size distributions from 4 to 440 nm with the small column and 8 nm to 1.2 µm with the large column

- Continuous and fast scanning measuring principle

- High resolution in up to 128 size classes / decadeFor concentrations up to 108 particles/cm3 suitable

- Can be universally connected to DMAs and nanoparticle counters from other manufacturers*.

- Graphical display of measurement data

- Intuitive operation through 7" touch screen and GUI

- Integrated data logger

- Supports multiple interfaces and remote access

- Low maintenance

- Reliable function

- Reduces your operating costs

Applications:

- Filter test

- aerosol research

- Environmental and climate studies

- Long-term measurements 24/7/365

- inhalation studies

- Interior and workplace measurements

U-SMPS 2050 X / 2100 X / 2200 X

Universal Scanning Mobility Particle Sizer for various applications from 8 - 1200 nm with built-in X-ray ionisationThe SMPS system from Palas is available with X in the product name with a soft X-ray source as neutraliser. Compared to radioactive neutralisation (e.g. with Kr-85), this has the advantage that no restrictions have to be observed during transport and operation of the unit. The built-in X-ray source does not require notification or approval according to the Radiation Protection Ordinance (StrlSchV).

For further information we are at your disposal, you can contact us via contact form or by phone 044'746'3220.