Liquid atomizer with two-substance nozzle and downstream cyclone for separating large droplets

The AGF series is characterised in particular by its robust design, easy handling and long service life.

The AGF series consists of a combination of a two-substance nozzle with a downstream cyclone. The AGF 2.0 has a cyclone with the cutoff diameter dCutoff = 2 µm, the AGF 10.0 has a cyclone with the cutoff diameter dCutoff = 10 µm.

The maximum particle concentration of the AGF series is approx. 107 particles/cm3. Due to the cyclone, the maximum particle size can be calculated independently of the liquid.

Large droplets generate high mass flows and can contaminate filters, for example, in such a way that the filters are evaluated better than they are by the droplet loading during the filter test.

The AGF series is used very successfully for the generation of test aerosols, in clean room technology, for testing compressed air filters and for LDA measurements.

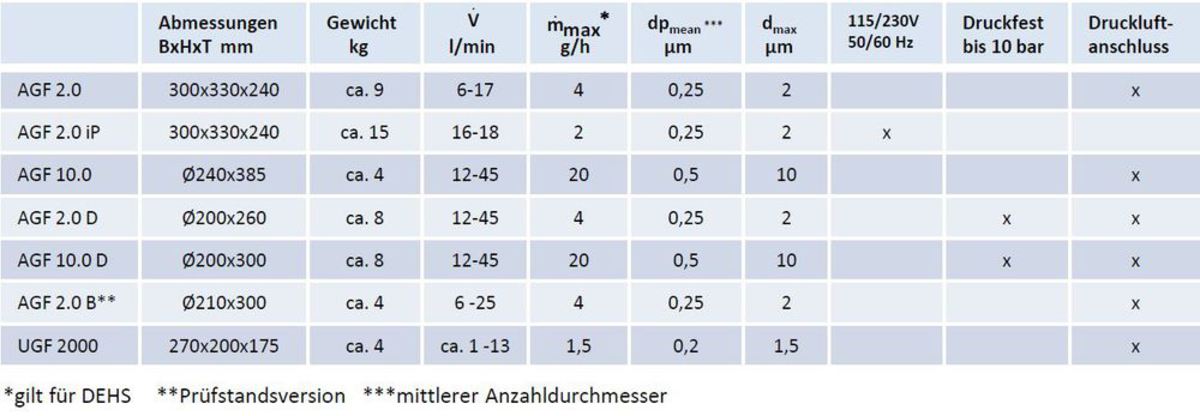

Overview of the AGF and UGF systems

AGF 10.0

Liquid nebuliser with two-substance nozzle and cyclone (selectivity 10 µm) acc. to VDI 3491-6

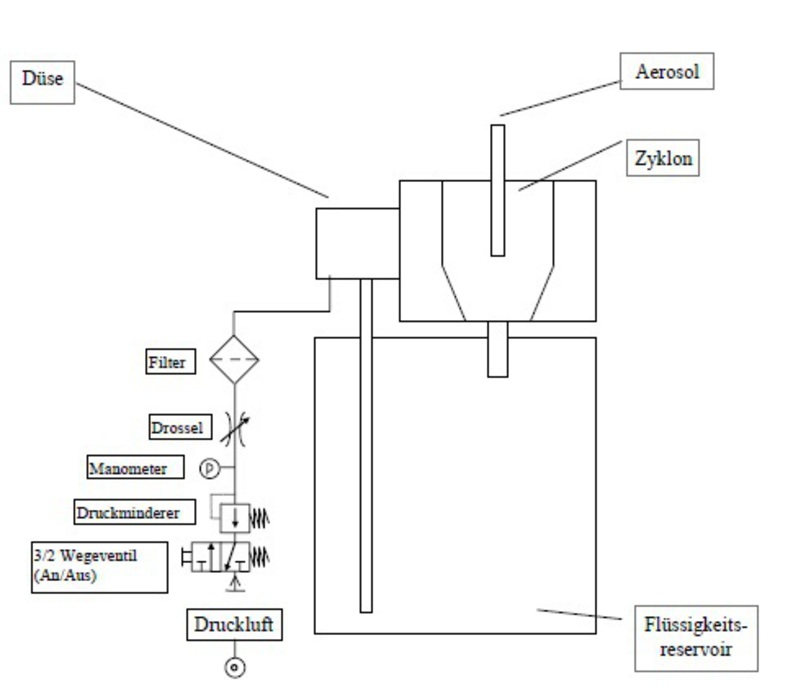

The AGF 10.0 is an aerosol generator for atomizing liquids and latex suspensions with constant particle rate and defined particle spectrum. The AGF 10.0 system consists of a controllable two-substance nozzle for setting the desired mass flow and a cyclone with a separation efficiency of 10 µm. The figure shows a schematic arrangement of the generator components:

Commissioning and start-up

The material to be dispersed is filled into the storage container and the AGF 2.0 is connected to a compressed air connection. The mass flow of the liquid can be infinitely adjusted via the nozzle pressure using a manometer. The droplet mist generated by the nozzle flows tangentially into a cyclone. Large particles are separated here by centrifugal forces and drip back into the storage container. The remaining droplets leave the cyclone through the so-called "immersion tube". The size spectrum of these droplets is determined on the one hand by the primary droplet spectrum generated by the nozzle and on the other hand by the separation characteristics of the cyclone.

The separation grain size can be calculated: daerodyn.max = 10 µm, i.e. independent of the liquid to be atomized, the maximum particle size is daerodyn ≈ 10 µm.

AGF 2.0

Liquid nebuliser with two-substance nozzle and cyclone (dp_max = 2 µm) according to VDI 3491-1 and -2

The AGF 2.0 system consists of a controllable two-substance nozzle for setting the desired mass flow and a cyclone with a selectivity of 2 µm. This means that virtually no particles > 2 µm are produced.

Functional principle of the AGF series incl. cyclone

commissioning

The material to be dispersed is filled into the storage container and the AGF 2.0 is connected to a compressed air connection. The mass flow of the liquid can be infinitely adjusted via the nozzle pressure using a manometer. The droplet mist generated by the nozzle flows tangentially into a cyclone. Large particles are separated here by centrifugal forces and drip back into the storage container. The remaining droplets leave the cyclone through the so-called "immersion tube". The size spectrum of these droplets is determined on the one hand by the primary droplet spectrum generated by the nozzle and on the other hand by the separation characteristics of the cyclone.

The separation grain size can be calculated: daerodyn.max = 2 µm, i.e. independent of the liquid to be atomized, the maximum particle size is daerodyn ≈ 2 µm.

AGF 3000

Aerosol generator with refill unit for loading compressed air filters under overpressure up to 7 bar

The AGF 3000 was specially developed to pressurize compressed air filters according to ISO 12500 until the compressed air filter is saturated. The AGF 3000 system consists of an aerosol generator and an automatic refill unit. The AGF 3000 has a two-substance nozzle developed by Palas® with which even very high mass flows of up to 29 g/h can be achieved. The aerosol generator AGF 3000 is pressure-resistant up to 7 bar overpressure (higher pressures on request).

Commissioning

The liquid to be dispersed is simply filled into the storage container. The mass flow is adjusted by the volume flow through the nozzle. The volume flow through the special two-substance nozzle is continuously controlled by a mass flow controller.

A sensor measures the filling level in the storage tank. If the level falls below the minimum filling level, the storage tank of the aerosol generator is automatically filled up to the maximum filling level via the separate refill unit.

Advantages of the AGF series:

- Generation of high mass flows up to approx. 29 g/h

- Pressure resistant up to 7 bar (AGF 3000)

- Exact setting of the operating parameters

- Number concentration CN can be varied by a factor of 10.

- Particle size distribution remains practically constant when CN is changed

- Number distribution maximum lies in the MPPS range

- Virtually no power losses

- Optimum concentration, no coagulation losses

- Resistant to many acids, alkalis and solvents

- Robust design, stainless steel housing

- Simple operation

- Long dosing time

applications:

- Clean room technology

- Acceptance measurements and leak test according to ISO 14644 and VDI 2083

- Leak test, fit test

- recovery time measurement

- Filter testing, quality control

- filter cartridges

- Car cabin filter

- Filter media, particle filters, HEPA/ULPA filters

- compressed air filter

- tracer particles

- optical flow measurement method in overpressure up to 10 bar (model variant AGF 10.0 D)

- inhalation experiments

- LDA

- Calibration of counting particle measurement methods

- Nebulisation of latex suspension < 5 µm at AGF 10.0

- Test of smoke detectors