Aerosol generator for defined atomization of oils

The PLG 2000 is a cold nebuliser which should be used in air-conditioned rooms. If air conditioning of the room is not possible, a heatable version of the unit, e.g. PLG 2000 H, should be used.

Commissioning

The liquid to be dispersed is simply filled into the storage container. The nozzle system developed by Palas® is immersed in the liquid. This nozzle system is based on the Laskin principle and guarantees an extremely precise dosing constancy with constant particle size. The mass flow is adjusted via the volume flow through the nozzle. The volume flow is controlled via a pressure reducer and manometer on the unit.

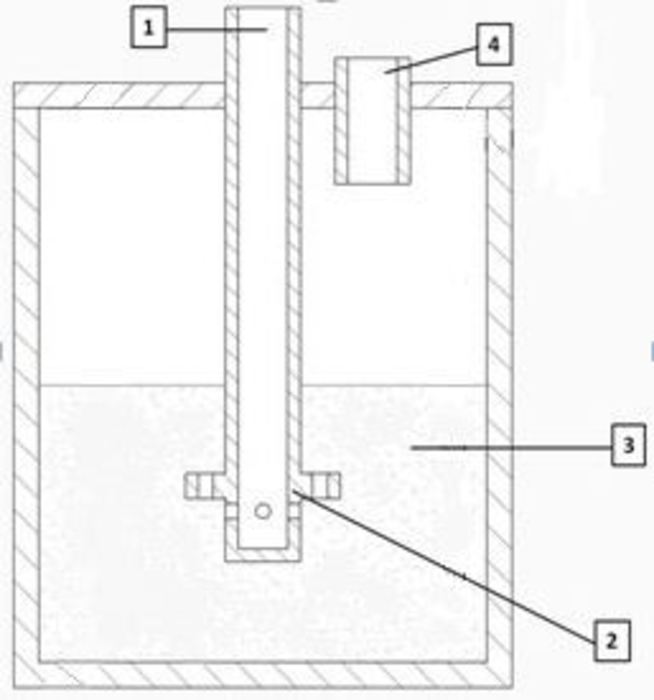

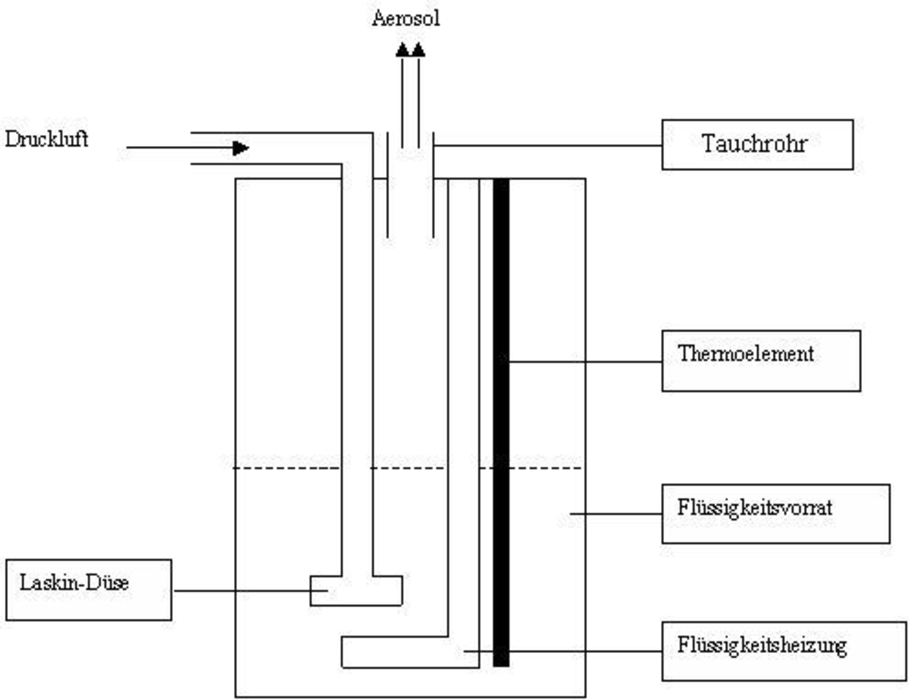

Fig. 2: Functional principle PLG series

legend

1) Compressed air

2) Special Laskind nozzle

3) Aerosol substance

4) Aerosol outlet

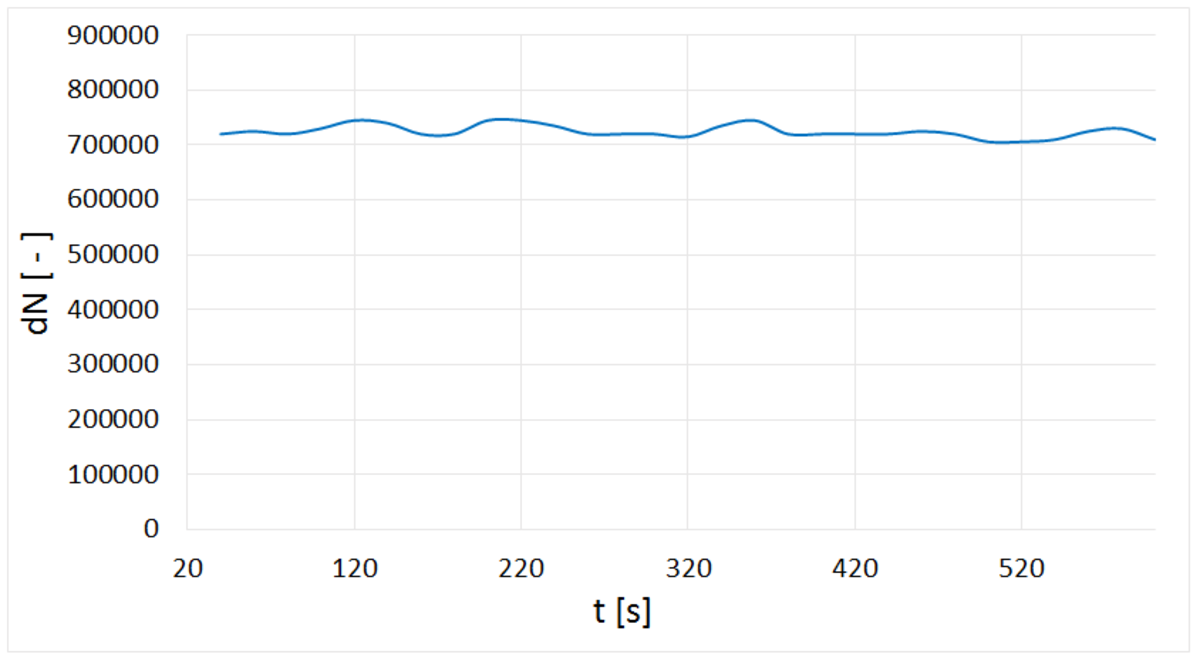

This nozzle system is based on the Laskin principle and guarantees extremely precise dosing consistency with constant particle size (see Fig. 3).

Fig. 3: High constancy of particle concentration over time at a resolution of 30 s

The PLG 2000 delivers a maximum mass flow of approx. 20 g/h (depending on the aerosol substance used).

PLG 2000 H

Heatable version of the PLG 2000 up to 100°C

In contrast to the PLG 2000, the PLG 2000 H has an integrated heating up to 100°C.

The temperature control of the oil changes both the number concentration and the particle size distribution of the material to be dispersed due to a change in viscosity. This means that materials can also be dispersed which cannot be cold-atomised because of their viscosity.

The PLG 2000 H Generator consists of a Laskin nozzle, a liquid heater and a thermocouple to control the temperature. The immersion tube is the aerosol outlet. The aerosol can be transported to the place of use by means of an attached hose. The liquid to be atomized can be heated up to 100°C. The aerosol can be removed by means of a hose.

The PLG 2000 H meets the requirements of the EN 779 standard for ventilation filters. The PLG 2000 H is also used for testing oil mist separators.

Advantages:

- Very good short-term and long-term dosing consistency

- Best reproducibility regarding particle size distribution and particle concentration

- Large mass flow range (very low and very high)

- Robust design (optionally resistant to chemically aggressive liquids)

- Compact and lightweight

- Simple operation, proven in industrial applications

- Reliable function

- Low maintenance

applications:

- Filter industry/oil separators

- separation efficiency determination

- Determination of fractional separation efficiency

- loading test

- Test of cooling lubricant separators

- Comparison of particle measuring instruments

- tracer particles

- flow visualization