Aerosol generator for generating monodisperse and uncharged droplets, dp = 0.2 - 8 µm

function

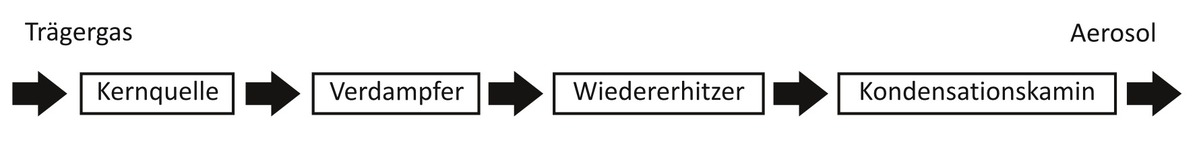

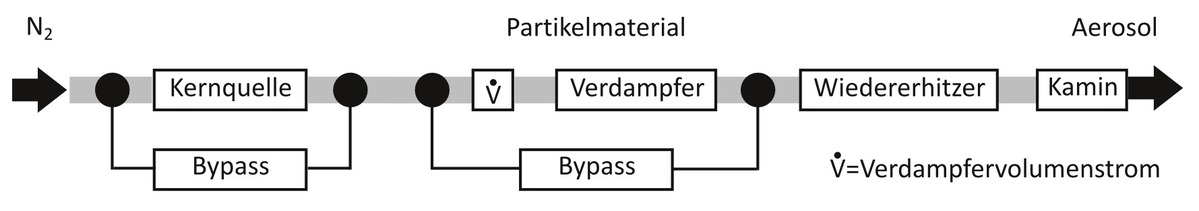

The MAG 3000 works on the principle of Sinclair-LaMer (1943). It consists of a core source for generating the condensation nuclei with a particle diameter of approx. 85 nm, an evaporator for evaporating the particle material, a reheater and a condensation stack in which the particle material condenses on the condensation core. This is a heterogeneous condensation process.

The "heart" of the MAG 3000 is the core source developed by Palas® with the bypass technology. No drying line!

Aufbau Sinclair-LaMer

Aerosol generator construction Palas MAG 3000

The new core source nebulises only approx. 20 ml of the salt solution in 10 hours and does not require a drying section due to the very small droplets.

Conventional Sinclair LaMer generators, like Palas® GmbH in the past, use a so-called collison atomizer. The concentration constancy, the high mass flow and the therefore required drying section did not meet our quality requirements regarding reliability and simple operation.

Commissioning and setting the particle size

1. temperature change in the evaporator (Fig. 3)

If the temperature in the evaporator is increased, more steam is generated per time. With the same core concentration, more particle material is available for each core and the particle diameter increases. This process is stable after a few minutes.

2nd bypass around the evaporator (Fig. 3)

A rapid change in particle size by a factor of approx. 2.5 is achieved with this bypass in approx. 10 seconds. By opening this bypass valve, less steam is discharged from the evaporator and the particle diameter becomes smaller.

3. bypass around the core source (Fig. 3)

By opening the bypass valve of the core source, fewer cores enter the evaporator and larger particles are produced in approx. 10 seconds. This bypass is used to generate particles > 5 µm.

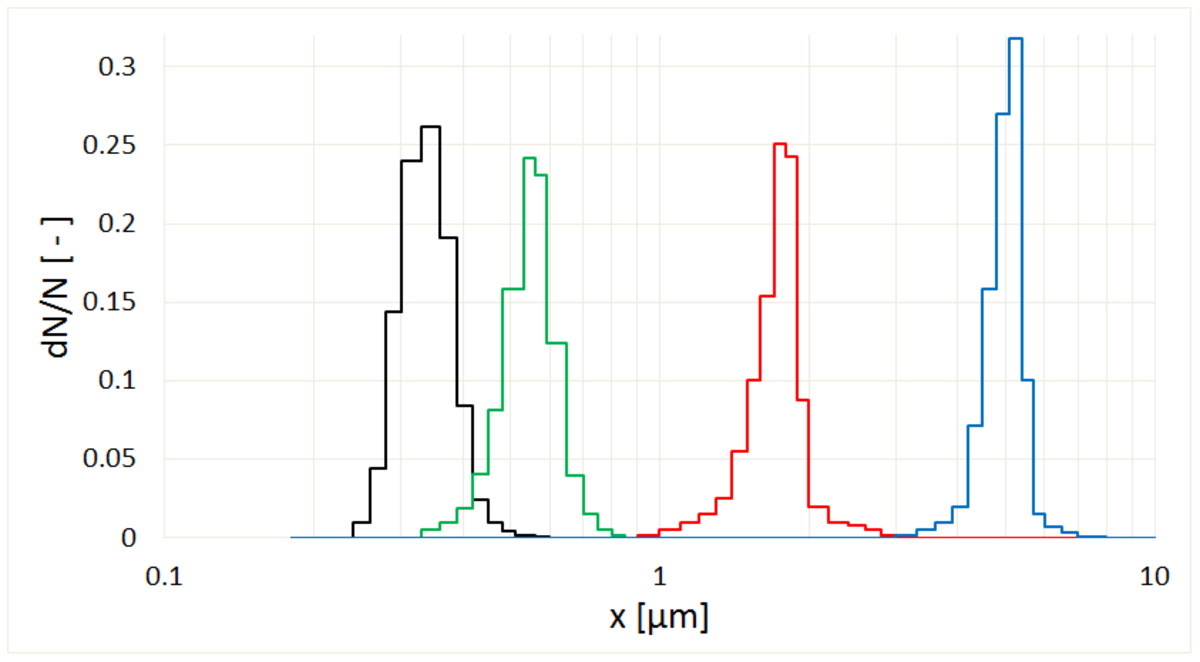

The MAG 3000 meets all definitions of monodispersity according to VDI 3491 - Sheet 4.

This graph shows the narrow particle size distributions that can be generated with the MAG 3000.

Monodisperse particle size distributions

Advantages:

- particle size adjustable from approx. 0.2 - 8 µm for DEHS (other particle materials on request)

- Reproducible particle size adjustment (uncharged aerosols)

- Minimum consumption of saline solution, approx. 20 ml in 10 h

- No drying line, no silica gel

- Reliable bypass settings for boiler and core source

- Fast particle size change up to a factor of 2.5 due to bypass settings in approx. 10 s

- Robust design

- Reliable function, high reproducibility

- Low maintenance

- Reduces your operating costs

applications:

- Calibration of particle measuring instruments

- Comparison of device characteristics as a function of particle size:

- Resolving power

- classification accuracy

- lower counting efficiency

- upper counting efficiency

- boundary zone error

- inhalation tests

- Tracer particles/flow visualization

- filter testing